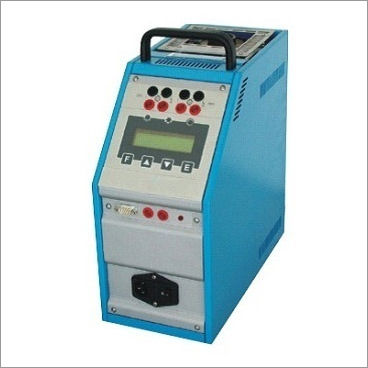

High Power Thermocouples

Product Details:

- Product Type High Power Thermocouple

- Material High-grade Nickel Chromium / Platinum / Ceramics

- Application Furnace, Kiln, Foundry, Industrial Heating Equipment

- Temperature Range Up to 1800C

- Heat Resistance Yes

- Insulation Resistance Greater than 100 M at 500V DC

- Dimension (L*W*H) Customizable as per requirement

- Click to View more

X

High Power Thermocouples Price And Quantity

- Threaded or flange mounting

- Factory-calibrated

- Class 1 as per IEC standards

- Sheathed with high purity ceramic or Inconel

- Industrial grade plug or custom termination

- Fast response, less than 10 seconds

- 0% to 95% RH (non-condensing)

- K (NiCr-Ni), R, S, B, N types available

- Standard 1 meter / Custom length on request

- Solid or stranded thermocouple wire available

High Power Thermocouples Product Specifications

- Furnace, Kiln, Foundry, Industrial Heating Equipment

- Greater than 100 M at 500V DC

- Standard: 20 mm / Customizable

- Yes

- Up to 1800C

- Customizable as per requirement

- High Power Thermocouple

- High-grade Nickel Chromium / Platinum / Ceramics

- Threaded or flange mounting

- Factory-calibrated

- Class 1 as per IEC standards

- Sheathed with high purity ceramic or Inconel

- Industrial grade plug or custom termination

- Fast response, less than 10 seconds

- 0% to 95% RH (non-condensing)

- K (NiCr-Ni), R, S, B, N types available

- Standard 1 meter / Custom length on request

- Solid or stranded thermocouple wire available

Product Description

We are a renowned organization, which deals in high power thermocouple. The thermocouple is an efficient equipment, demanded in the industrial sectors. It is often installed in the home appliances too. The primary objective of this product is to measure the temperature. This helps in monitoring and recording the accurate temperature data. It is light in weight, hence is portable. The high power thermocouple does not lose its accuracy with the frequent use. We guarantee the satisfying output of the provided device.

Specification

| Material | Stainless Steel |

| Types | J,K,T,E,R and resistor sensor |

| Range | Plain,bayonet,washer,leaf and ring types |

| Application | Industrial, Household |

Superior Accuracy and Rapid Response

Designed with reference to IEC Class 1 standards, our high power thermocouples guarantee precise measurements. Thanks to their fast response timetypically less than 10 secondsthe sensors provide timely and reliable temperature data, even in rapidly changing industrial environments. This ensures optimal process control and enhances operational safety in critical applications.

Advanced Construction for Maximum Durability

Built with high-purity ceramic or Inconel sheathing, these thermocouples exhibit high thermal resistance, making them suitable for extreme temperatures up to 1800C. The use of high-quality Nickel Chromium, Platinum, and ceramic materials further boosts their dependability in harsh operating conditions, extending service life and lowering maintenance requirements.

Flexible Configurations to Suit Every Application

We offer both solid and stranded wire options, with standard 1-meter leads or custom lengths on request. Choose from various connector types and mounting solutionsthreaded or flangedto meet the unique requirements of your plant. Customizable disc diameters and dimensions ensure a seamless fit, enhancing integration with existing furnace, kiln, or heating systems.

FAQs of High Power Thermocouples:

Q: How are these high power thermocouples typically used in industrial environments?

A: They are primarily installed in furnaces, kilns, foundries, and industrial heating equipment to provide accurate, real-time temperature measurement and control where extremely high temperatures and harsh conditions are prevalent.Q: What makes these thermocouples accurate and reliable for high-temperature applications?

A: Compliant with IEC Class 1 accuracy requirements, they utilize high-grade materials such as Nickel Chromium, Platinum, and ceramics. The advanced sheathing and superior insulation resistance ensure precise and reliable data, even in challenging environments up to 1800C.Q: When should I request a custom configuration for my thermocouple order?

A: A custom configuration is needed when your application requires specific lead lengths, disc diameters, mounting styles, or unique termination types that differ from standard offerings. This ensures flawless integration and maximum sensor performance in your system.Q: Where can these thermocouples be installed, and what are their mounting options?

A: They are suitable for installation in a range of industrial equipment, including furnaces, kilns, and heating systems. Mounting options include threaded connections or flange mounting, depending on the specific needs and setup of your equipment.Q: What is the calibration process for these thermocouples?

A: Each thermocouple is factory-calibrated in accordance with industry standards to ensure measurement accuracy. Calibration certificates can be provided upon request, enhancing quality assurance for critical industrial operations.Q: How do I benefit from the high insulation resistance feature?

A: An insulation resistance of greater than 100 M at 500V DC minimizes the risk of signal loss and interference, ensuring stable readings and increased operational safety, especially in high-humidity or electrically noisy environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese