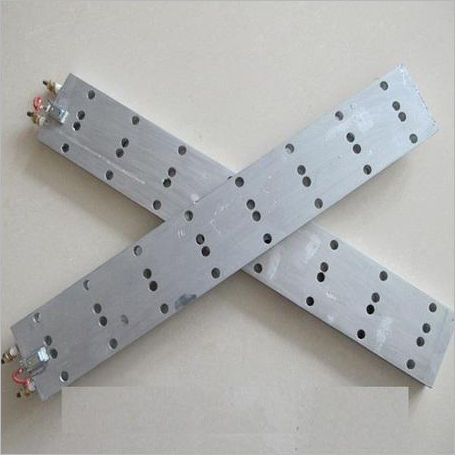

Aluminum Cast-In Heaters

Product Details:

- Heating Element Nickel Chromium Resistance Wire

- Features Corrosion Resistant, Uniform Heat Distribution, Long Service Life, High Thermal Conductivity

- Usage Industrial Heating, Barrel Heating, Die/Tool Heating

- Application Areas Plastic Processing, Extruders, Blow Molding, Injection Molding, Packaging Machinery, Food Processing Equipment

- Diameter 25 mm 500 mm or as specified

- Voltage 110V 440V (as required)

- Mounting Type Flange or Clamp Mounting

- Click to View more

X

Aluminum Cast-In Heaters Product Specifications

- Flange or Clamp Mounting

- Round/Cylindrical

- Ceramic/Mica Insulation

- 110V 440V (as required)

- Single Phase/Three Phase

- Screw, Lead Wire, or Customized

- 50/60 Hz

- Up to 350C

- Industrial Heating, Barrel Heating, Die/Tool Heating

- Corrosion Resistant, Uniform Heat Distribution, Long Service Life, High Thermal Conductivity

- Nickel Chromium Resistance Wire

- 25 mm 500 mm or as specified

- 1 kW 15 kW (customizable)

- Plastic Processing, Extruders, Blow Molding, Injection Molding, Packaging Machinery, Food Processing Equipment

- High Grade Aluminum Alloy

- Available as per Drawing/Requirement

- 6 mm 35 mm as per application

- Meets International Quality Standards

- Smooth Aluminium Finish for Efficient Heat Transfer

- Suitable for Moist, Dusty and High-Temperature Areas

- Optional Built-In

- Flexible Leads, Lugs, Terminal Box

- IP54 or Higher on Request

- Thermocouple or RTD sensor integration possible

Product Description

Experience a Price Cut on our famed Aluminum Cast-In Heaters, highly recommended for unassailable performance in industrial heating. Get smooth aluminium finish for efficient heat transfer and valorous reliability in moist, dusty, and high-temperature environments. Available in round/cylindrical shapes, customizable to your requirements with thickness from 6 mm to 35 mm, and diameter from 25 mm to 500 mm. Benefit from optional thermal lagging, IP54+ ingress protection, corrosion resistance, and uniform heat distribution. Control options include integrated thermocouples or RTD sensors, with versatile mounting and connection options. Manufactured in India using high-grade aluminum alloy, these heaters deliver longevity and international quality standards.

Aluminum Cast-In Heaters: Efficient & Versatile Solutions

Aluminum Cast-In Heaters stand out for their high thermal conductivity and durability. Their smooth finish ensures optimal heat transfer, making them ideal for both general and specific industrial uses such as barrel heating, die/tool heating, and plastic extrusion. Highly versatile, these heaters support commercial applications in packaging, food processing, and injection molding machinery. Their customization options enable tailored solutions, meeting industry standards and maximizing operational efficiency.

Delivery Time, Market Reach & Sample Availability

Our Aluminum Cast-In Heaters are delivered promptly through quick dispatch processes, boosting your market value and competitive advantage. We export to main markets across Asia, Africa, Middle East, and Europe, meeting varying industrial requirements. Samples are available to ensure you receive the perfect fit for your specifications before placing bulk orders. Count on reliable delivery schedules and trusted customer support for your global supply needs.

Aluminum Cast-In Heaters: Efficient & Versatile Solutions

Aluminum Cast-In Heaters stand out for their high thermal conductivity and durability. Their smooth finish ensures optimal heat transfer, making them ideal for both general and specific industrial uses such as barrel heating, die/tool heating, and plastic extrusion. Highly versatile, these heaters support commercial applications in packaging, food processing, and injection molding machinery. Their customization options enable tailored solutions, meeting industry standards and maximizing operational efficiency.

Delivery Time, Market Reach & Sample Availability

Our Aluminum Cast-In Heaters are delivered promptly through quick dispatch processes, boosting your market value and competitive advantage. We export to main markets across Asia, Africa, Middle East, and Europe, meeting varying industrial requirements. Samples are available to ensure you receive the perfect fit for your specifications before placing bulk orders. Count on reliable delivery schedules and trusted customer support for your global supply needs.

FAQs of Aluminum Cast-In Heaters:

Q: How are Aluminum Cast-In Heaters customized for specific industrial requirements?

A: Aluminum Cast-In Heaters can be tailored to customer drawings, application specifications, and unique power, voltage, and mounting needs. Options include thermal lagging, ingress protection, and a range of connection and control features to suit diverse industrial uses.Q: What is the recommended process for integrating a control system like a thermocouple or RTD sensor?

A: Control systems such as thermocouples or RTD sensors can be directly integrated into the heater design during manufacturing, allowing accurate temperature measurement and regulation as per application requirements.Q: When should thermal lagging be used with cast-in heaters?

A: Thermal lagging is recommended when minimizing heat loss is critical or when working in environments where maintaining surface temperature is essential for process stability. It can be optionally built into the heater upon request.Q: Where can Aluminum Cast-In Heaters be most effectively used?

A: These heaters excel in moist, dusty, or high-temperature settings, making them suitable for plastic processing, extrusion, blow molding, injection molding, packaging machinery, and food processing equipment.Q: What benefits do users gain from the smooth aluminium finish and corrosion-resistant features?

A: The smooth aluminium finish provides efficient heat transfer and prevents uneven heating, while corrosion resistance ensures long service life and reliability in harsh industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese