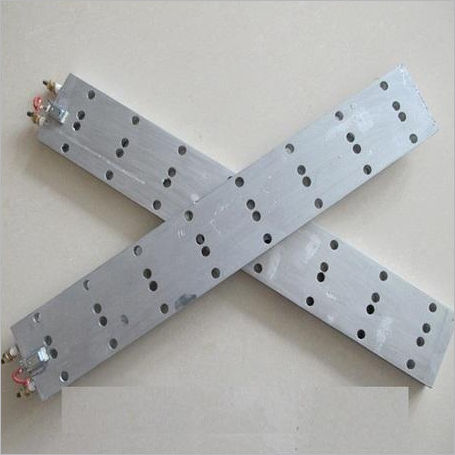

Electric Cast-in Heaters

Product Details:

- Mounting Type Flange Mounting, Threaded, Bolt-on

- Terminal Type Screw, Lead Wire, Pin Type

- Application Areas Extruder, Injection Moulding Machines, Packaging Equipment, Dies and Molds

- Diameter Custom as per requirements

- Temperature Up to 400C

- Frequency 50 Hz / 60 Hz

- Phase Single Phase / Three Phase

- Click to View more

X

Electric Cast-in Heaters Product Specifications

- Custom as per requirements

- Rectangular, Circular, Custom

- Aluminum Alloy, Brass

- Extruder, Injection Moulding Machines, Packaging Equipment, Dies and Molds

- Screw, Lead Wire, Pin Type

- Flange Mounting, Threaded, Bolt-on

- Up to 40 kW

- 110 V, 230 V, 415 V

- Nichrome Wire, Stainless Steel

- High thermal efficiency, Uniform heating, Long service life, Rugged construction

- Mica, Ceramic

- Up to 400C

- Single Phase / Three Phase

- 50 Hz / 60 Hz

- Industrial Heating, Molding, Extrusion

- Customizable, Up to 2 meters

- Optional

- IP65

- Dry/Protected Areas

- Standard and Customized

- Yes

- Anodized, Powder Coated

- 6 W/cm²

Product Description

Discover the outstanding Electric Cast-in Heaters, now offered at a reduced market value. Get It Now to experience sizzling performance and uncommon versatility in industrial heating solutions. Engineered with a towering watt density of up to 6 W/cm and a robust IP65 ingress protection rating, these heaters provide uniform, high thermal efficiency. Available in anodized or powder-coated finishes, they feature customized sizes, shapes, and connections, with mounting options for every installation. Built using aluminum alloy, brass, and advanced insulation like mica and ceramic, our heaters withstand temperatures up to 400C, making them ideal for molding, extrusion, dies, and packaging applications. Optional thermocouple, variable lead lengths, and reliable construction guarantee a long service life.

Application Areas and Industrial Usage

Electric Cast-in Heaters find wide application in extruder machines, injection moulding, dies, molds, and packaging equipment. Used primarily for industrial heating, molding, and extrusion processes, these heaters assure uniform and efficient heat transfer. Thanks to customizable sizes, shapes, and mounting styles, industries can adapt them for both new installations and upgrades. Their robust construction ensures reliable long-term operation in dry, protected areas, safeguarding continuity in demanding environments.

FOB Port, Delivery Time, and Sample Availability

Transportation of Electric Cast-in Heaters is managed through major FOB ports across India, with prompt delivery times estimated for every shipment. Manufacturers and exporters honor competitive market value, ensuring the product arrives when needed. Sample units are available for evaluation purposes, enabling customers to verify specifications and performance before placing large orders. Reliable logistics and expert support guarantee a stress-free buying experience.

Application Areas and Industrial Usage

Electric Cast-in Heaters find wide application in extruder machines, injection moulding, dies, molds, and packaging equipment. Used primarily for industrial heating, molding, and extrusion processes, these heaters assure uniform and efficient heat transfer. Thanks to customizable sizes, shapes, and mounting styles, industries can adapt them for both new installations and upgrades. Their robust construction ensures reliable long-term operation in dry, protected areas, safeguarding continuity in demanding environments.

FOB Port, Delivery Time, and Sample Availability

Transportation of Electric Cast-in Heaters is managed through major FOB ports across India, with prompt delivery times estimated for every shipment. Manufacturers and exporters honor competitive market value, ensuring the product arrives when needed. Sample units are available for evaluation purposes, enabling customers to verify specifications and performance before placing large orders. Reliable logistics and expert support guarantee a stress-free buying experience.

FAQs of Electric Cast-in Heaters:

Q: How do Electric Cast-in Heaters benefit industrial heating processes?

A: Electric Cast-in Heaters provide outstanding thermal efficiency and uniform heating, maximizing productivity while minimizing energy costs. Their rugged construction ensures a long service life even in intensive applications.Q: What materials are used in the manufacturing of these heaters?

A: The heaters are crafted from high-quality aluminum alloy and brass, with insulation materials including mica and ceramic. This combination ensures durability and optimal performance in varied industrial environments.Q: Where can these heaters be installed and used?

A: These heaters are ideal for installation in extruders, injection moulding machines, packaging equipment, dies, and molds. Custom shapes and mounting types allow their use in many industrial setups.Q: When can I expect delivery after placing my order?

A: Delivery times depend on transportation logistics and destination, but manufacturers aim to provide prompt and accurate shipping estimates from major Indian FOB ports, ensuring timely arrival of products.Q: What is the process for customizing the heater specifications?

A: Clients can specify desired size, shape, voltage, watt density, lead length, and mounting type during the ordering process. Manufacturers offer guidance to ensure all application requirements are met.Q: How is the thermocouple provision incorporated into the heater?

A: A thermocouple provision can be optionally added during production, allowing for precise temperature monitoring and control, tailored to your specific industrial needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese